The Why and How of Stretch Fabrics

Looking at fabric more closely

It is common to associate stretch fabric with spandex, however the story of what makes fabric stretchy is a bit more complex. In this article, I hope to touch on some aspects of why and how fabrics can be stretchy for anyone interested in considering fabric and fibers more closely.

I work with fabric everyday at Refiber Designs. From my experience, I want to share some of my understanding of stretch fabric and to explain everything as plainly as possible to make it accessible to any curious mind with or without a sewing background. I hope this article provides you with some new insights about stretch fabric.

Properties of Stretch

Let’s start by defining the 2 main aspects of stretch in relation to fabric:

1) the fabric’s ability to extend in length without breakage or damage.

This property is denoted by a percentage to communicate that a fabric’s length can increase by that amount. Stretch percentage for knit fabrics will be for the horizontal or vertical directions of the fabric. (For example, if you have a piece of fabric that is 100 cm in width that has 30% horizontal stretch, you should be able to stretch the width of the fabric up to 130 cm without harming the fabric.) This percentage is not always provided by retailers, but is still the standard way of notating stretch.

2) the fabric’s recovery, ability to spring back to its original shape after extending in length.

Recovery describes the pull-back when you stretch a fabric that helps the fabric return to the natural state that it was in before it was stretched. Often this is where spandex come into the equation.

How Fabrics Extend in Length:

In order to understand how fabric extends in length we will need to look closer at its structure. For now, let's ignore any innate stretch in the yarns within the fabric; it would only enhance the effects that we explore in this section. Without the stretch within the yarn, we are left with the mechanical stretch due to the way that the yarn is arranged within the constructed fabric.

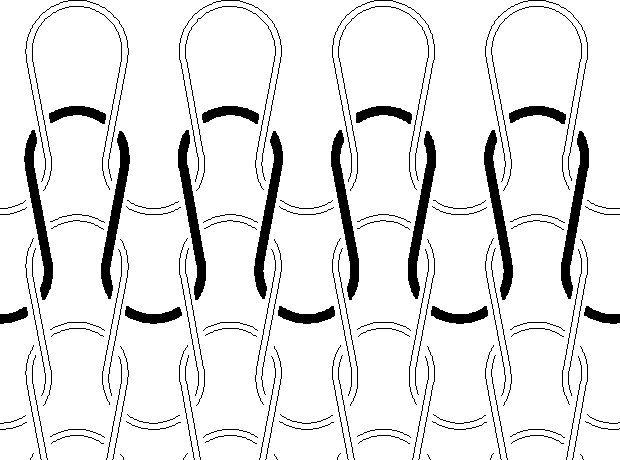

Figure 1: diagram demonstrating how interlocking loops of yarn can form a knit fabric (image licence) (source)

Knit Fabrics

Knit fabrics are made of interlocking loops of yarn (see figure 1). The looping design of knit fabrics can allow even non-stretchy yarns to condense and straighten out when pulled, which lengthens the fabric in the given direction. The tightness of the knit will affect the yarn’s ability to straighten out and will thus affect the amount of stretch. Knit fabrics can also have different ways of arranging the loops together to form different textures or looks to the fabric, but the main principles about the stretch are the same.

Figure 2 shows how the loops within a fabric change when the fabric is stretched horizontally and vertically. You can test this out yourself by looking closely while stretching a small section of a knit t-shirt.

Figure 2: stretching knit fabric, an example with simplified diagrams of jersey knit fabric, copyright © Refiber Designs

Woven Fabrics

Woven fabrics are made up of intertwined yarns lined up in perpendicular axes called the warp and weft (see figure 3). Woven fabrics are considered, more or less, not stretchy (unless they contain spandex fibers); however there is some stretch along the diagonal of the weave, known as the bias.

The stretch along the bias is a commonly utilized property in clothing construction. The bias often provides better movement and drape to dresses and skirts. Employing the bias in neckties is perhaps a more obvious use-case for stretch comfort around the neck.

The bias stretches for the same reason that knit fabrics stretch: when pulled, the threads have room to move and extend in the direction of the stretch (see figure 4). This is in contrast to trying to pull on the fabric in-line with the weave of the fabric where there is no stretch because the fibers are already extended out as far as they can in this direction. So technically there is some amount of stretch in any direction that is not parallel with the yarns in the fabric, but the bias, at 45 degrees, allows for the maximum stretch of the fabric.

Figure 3: diagram demonstrating the structure of a basic woven fabric (source)

Figure 4: stretching woven fabric along the bias, an example with a basic weave, copyright © Refiber Designs

There is another potential way that woven fabric can have stretch due to how it is constructed. The warp is taut during production and the weft is woven under and over through the warp yarns. Depending on how tightly the fabric is woven, there can be some stretch as the weft yarns straighten out when pulled, as demonstrated in figure 5 which shows a cross-section of fabric. This type of stretch is probably most noticeable in thick woven rugs or handmade weavings, but is not likely to be noticeable in factory-made fine woven fabrics.

Figure 5: This diagram is looking directly into a slice of woven fabric. The circles represent the warp of the fabric and the intertwined lines represent the weft of the fabric. The lower image, in contrast to upper image, of this figure demonstrates the potential stretch in the direction of the weft of the fabric. (image license) (modified from this source).

When Fabric Stretches Out, and Might Not Recover

Particularly with clothing like knit sweaters, we may need to be conscientious of not stretching them out so that they become deformed. This is the reason why sweaters are typically laid flat to dry after washing and then folded for storage, as opposed to hung up, to prevent stretching from its own weight pulling itself down.

Washing, steaming or ironing is known to help reset the stretch of some fabrics; for example, you might notice that worn jeans loosen over time and then reset to a snugger fit after washing. Cotton fabrics are commonly known for shrinking in the wash, although it has been hypothesized that the cotton yarns are stretched out in the manufacturing process and then when you wash the final fabric, the water and heat cause the fibers to simply return to their natural state before the stretching. Similarly, we can use heat to straighten or curl our hair, but then it returns to normal after washing.

Even fabrics with good recovery can stretch out and not back if you stretch them too much because of breakage in the fibers.

How Recovery Works in Fabrics

Some Physics

Let us consider the fabric as a physical system at a state of equilibrium. The construction of the fabric creates a system of forces that holds the fabric together in its form instead of just some amorphous yarn. Then consider how a force is added to the system when the fabric is stretched; and when removed, the stretch recovery is a return to an equilibrium of the inherent forces. A perfectly elastic fabric would have a singular state of equilibrium that it recovers to when there are no external forces on the system. Some systems, like the sweater mentioned in the last section, can have the internal forces change after stretch so that there is a new equilibrium state.

Spandex

Spandex fibers are very stretchy and can be blended together with other fibers at different ratios to produce a desired percentage of stretch. The blended fibers are then spun into the yarn that is used to knit or weave into fabric.

The stretch properties of spandex come from the chemical composition of the fibers. I am not an expert in this area, but my basic understanding of how it works is as follows. The fiber strands contain 2 types of segments —short structural segments and long, soft formless segments. When you stretch out the fibers, the long segments straighten out, extending the length of the fiber. When the force is removed and the stretch is recovering, the long segments recoil to the natural state of the fiber that is defined by the structure and the bonds of the short segments.

Spandex is a key component for most modern stretch fabrics and makes clothing more durable to stretch by improving recovery.

A note about Elasticity and Recovery in Natural Fibers

Some natural fibers can have intrinsic elasticity that benefits recovery, but it may not make a significant difference when compared to the impact that the yarn and fabric construction have on the stretch of the fabric. But if you're curious about the elastic qualities of natural fibers, one example, wool, can have some natural recovery because the fibers are curly or wavy. Think about how curly hair on humans works —when you pull down on a curl of hair, it extends in length and then springs back up into shape; this would be consistent with wool fibers but on a smaller scale.

Stretch Fabric, a Technology

It's funny to think about the significance of stretch fabric as a technology because it is so commonplace in today's world. But I think we under-appreciate how much stretch fabric has positively impacted society. After spandex was introduced to the market in the 1960's, comfortable clothing that moves with us has become the expectation ever since. Whether its in knit t-shirts or in the subtle design of neckties, stretch in fabric is a vital part of the majority of the clothing in everyone's closets today.

(Clothing drawings in this blog post were all drawn by David Ring for Europeana Fashion and are all public domain and can be found on Wikimedia Commons.)

You may also like: